Manufacturer of Hydraulic Presses

What the machine needs to have and what the operator needs to know

Hydraulic presses are impressive pieces of machinery that are used to fabricate different products that we use in our day to day lives. Contrary to what some people might believe, these machines are not fully automated, meaning that someone needs to operate them in order for them to manipulate metal correctly.

Hydraulic machines, if not used properly, are extremely dangerous, so safeguarding the operator is a top priority when building such an impressive piece of machinery. Here are factors that need to be taken into consideration when operating or building a hydraulic press:

The operator:

It’s important that the hydraulic press operator receives the proper information needed to operate the machine before he can begin any type of work using a hydraulic press. He is the one that inserts the metal to be bent into the shop press and he has to make sure that everything is positioned correctly before activating the press. When the press cycle is complete, he is the only one who should be allowed to remove the transformed material. While operating the press, it’s imperative that the operator maintains a safe distance from the machine. If he executes a task without paying attention, he could severely injure himself by getting a hand or another body part stuck in the machine during operation.

Safeguarding the operator’s safety:

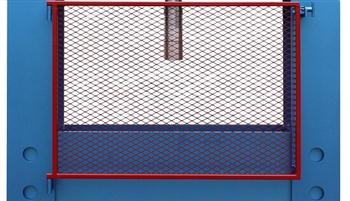

Safeguards incorporated to the machine will protect the operator from harm by creating a barrier between the press and the operator. However, it needs to be quickly removable in case of emergencies. According to the Occupational Safety and Health Administration (OSHA), many injuries could be avoided if all hydraulic presses we’re equipped with proper safety guards. In order to protect the operator even more, the motor of the hydraulic press should have no exposed parts or pulleys. It should also be installed up and out of the way and the controls of the machine should be locked away from the die area. The ram speed of the machine should be less than 3/8 of an inch per second which will allow a safe progression that will be easy to control.

Machinery Values is one of the largest machinery dealers in the world, specializing in high-quality, dependable H-frame presses, C-frame presses, hydraulic press brakes and hydraulic shears, which can be inspected on site in our 150,000 square foot facility in Harrison, NJ.